WHY CODESYS? The right choice for users and device manufacturers across all industries

Realizing an intelligent automation device with calculatable expenses and high market acceptance: Manufacturers of intelligent components benefit from the extensive features of CODESYS in the development of their devices.

Easy adaptation to different system requirements and environments

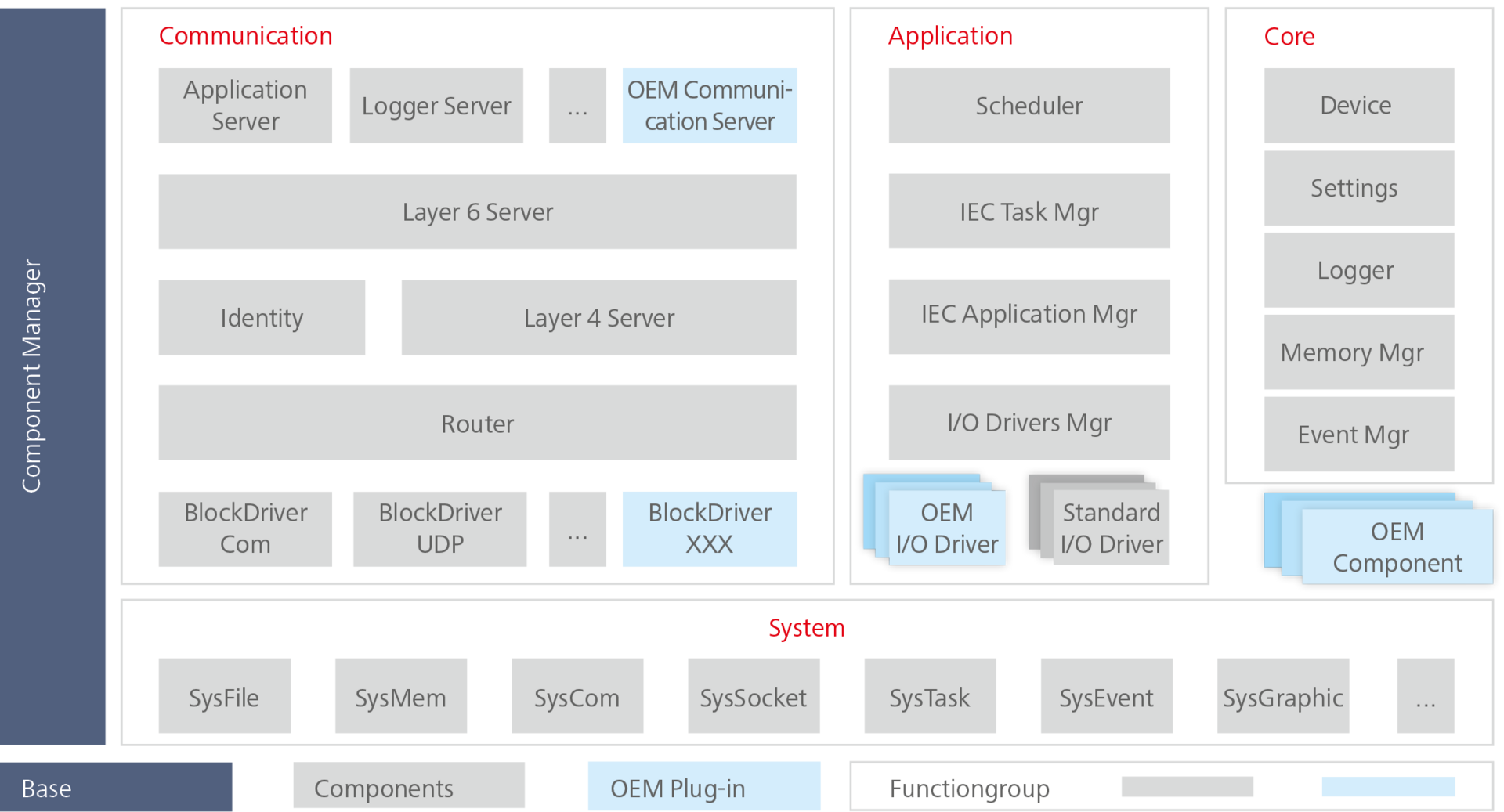

- Product available as a modular single-source runtime system for different device platforms

- Support for all common processors and operating systems for industrial systems, including native usage of multicore architectures (multicore support)

- Projectable development expenses: Development of industrial controllers with pronounced technical characteristics by means of defined interfaces and qualified adaptation support

- Numerous available reference systems and platforms (e.g. for popular Arm ® Cortex ® or embedded systems)

- Easy implementation of specific device properties by means of library modules (e.g. for own I/O functions)

- Adaptation and extendability of the user interface by manufacturer-specific plug-in modules (e.g. templates, editors, configurators, and wizards)

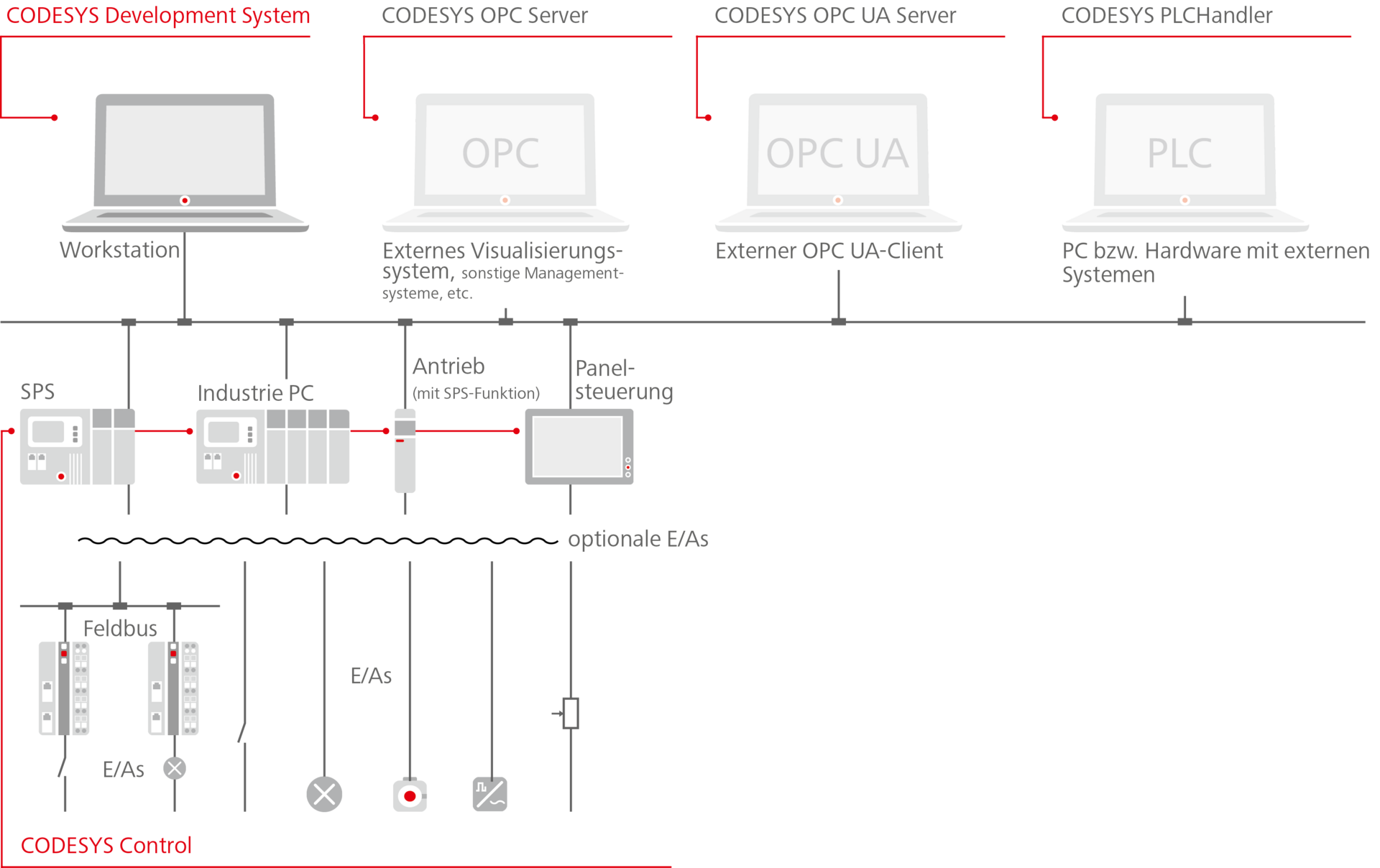

- Integration into existing system architectures by means of lean proprietary interfaces or standards, such as OPC / OPC UA

Size and functionality of the modular runtime system can be scaled.

Integrated functions for practice-oriented automation devices

- Configuration of popular fieldbus systems, own I/O modules or drives (e.g. for CANopen ® , EtherCAT ® , or PROFINET)

- Integrated visualization available as optional extension: Generation and display of practice-oriented user interfaces, e.g. directly on the device display, with connected screens or via web browser

- Numerous optional add-on products for fast scaling of the functional scope of the device (e.g. as motion controller, panel control, or communication gateway)

- Pre-certified software products for extending the standard controller into a TÜV-certified safety controller compliant with IEC 61508 SIL2 or SIL3

- Configuration and project engineering of industry-specific communication protocols (e.g. for building services control systems with BACnet ® )

- Optional interface for integrating existing or generated C code

With integrated add-on products, device manufacturers specify the scope of performance and primary application of their automation projects.

Reliable partner for successful automation devices

- The CODESYS Group: Product development by expert engineers and computer scientists by means of a proven, agile development framework (Scrum)

- Practice-oriented support from experienced project developers in the development of automation devices — from the initial idea to its implementation and product maintenance

- Fast response times to market demands with market-ready products: e.g. extend existing logic controllers to be flexible CNC controllers, provide them with integrated OPC UA servers, implement automated device and applications tests or TÜV-certified safety controllers

- Reliable maintenance, care, and quality assurance of all products and features by means of practical processes, ISO 9001-certified (since 2005)

- Long-term and confidential cooperation with device manufacturers from different branches and regions

- Transparent management with distinctive communication culture (e.g. by means of regular coordinating meetings at different levels, direct access to database for product improvement and ideas)

- High market acceptance of CODESYS-compatible automation devices by means of wide distribution among tens of thousands of users worldwide

- Services for common product marketing (e.g. at trade fairs, events, and online)

Benefits for users

End users employ CODESYS for successful creation of simple and sophisticated automation applications for industrial controllers that are used in factories, mobile machines, power and building automation systems, as well as many other areas. Several features and properties of the system help in this work.

Everything is integrated in a single user interface

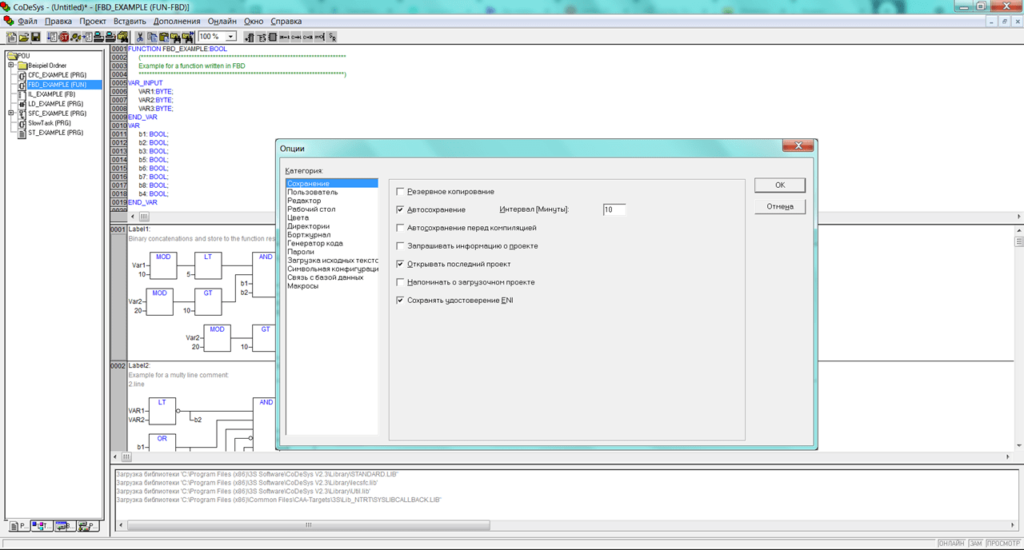

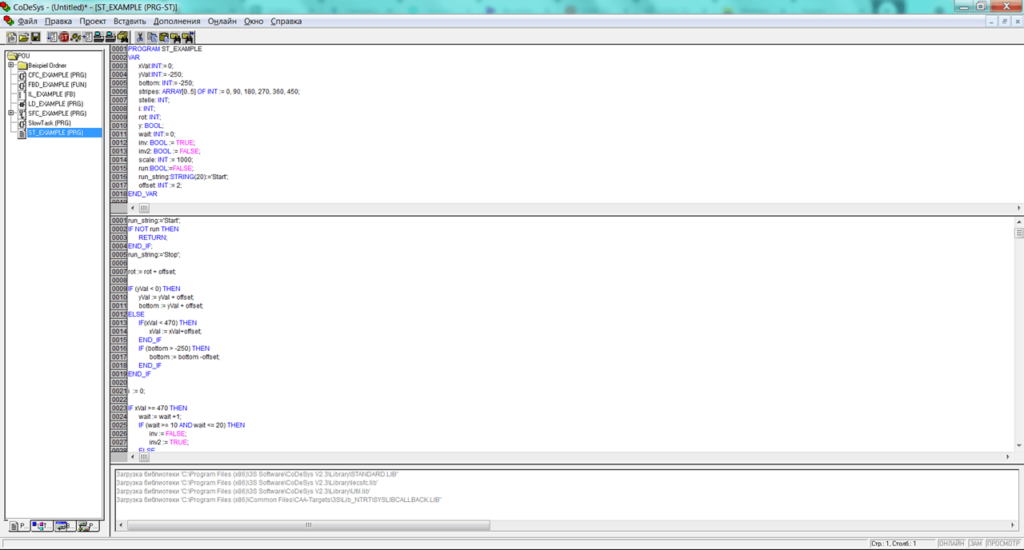

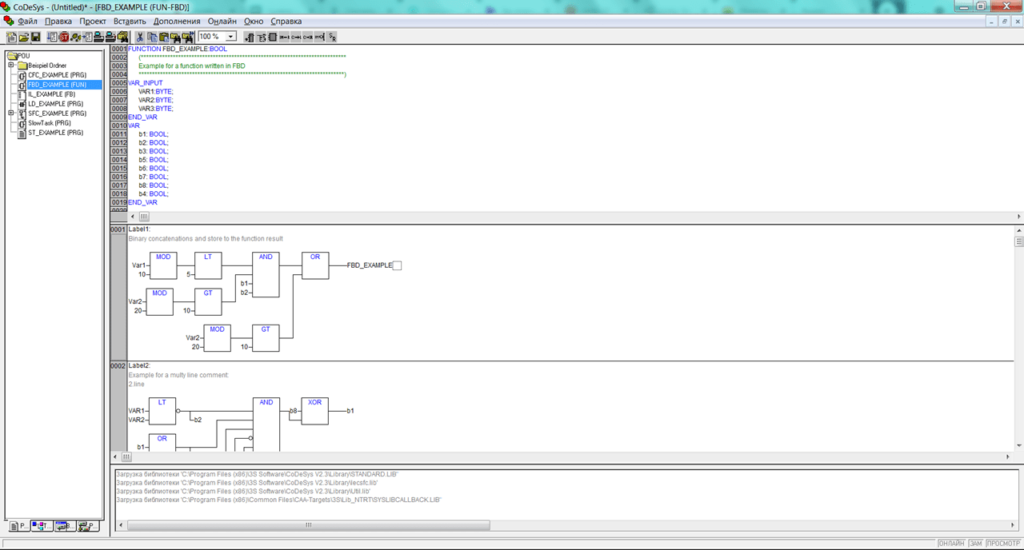

- Complete IEC 61131-3 programming system – from classic PLC programming to object-oriented controller programming

- Extensive features for convenient project engineering and commissioning of automation applications, such as data monitoring, scanning for application errors (debugging), and changing the application during operation (online change)

- Optional add-on modules for methodical application development: UML ® , version management, static code analysis, profiling, and test automation

- Configuration and commissioning of the most important industrial fieldbus systems or manufacturer-specific I/O systems

- Seamless integration of optional add-on components for project engineering: Visualization, motion control / CNC / robotics, safety modules

- Installation, maintenance, and training required only for a single user interface: Minimization of engineering effort

- Extendable function range through additional products available in the online store and with on-board tools (programming of function or communication libraries in the IEC 61131-3 languages, for example)

- Easy connection to a convenient Industry 4.0 platform for managing control landscapes per cloud

Программа codesys что это

CODESYS Services

Training, consulting, and development services directly from the manufacturer of CODESYS

CODESYS Automation Server

Industry 4.0- / IIoT platform for industrial automation

CODESYS Engineering

Professional Engineering of IEC 61131-3 Automation Projects

CODESYS Runtime

With the adaptable CODESYS Control runtime system, any kind of intelligent device is transformed into a complete IEC 61131-3 controller.

CODESYS Visualization

Creation of professional visualization interfaces, fully integrated in the PLC development system – with displays on target devices, PCs, and in web browsers

CODESYS Fieldbus

Integrated fieldbus support in the IEC 61131-3 tool – from CAN and PROFIBUS to Real-Time Ethernet protocol stacks included

CODESYS Motion+CNC

Logic and motion control in a single IEC 61131-3 system: Development kit for project engineering, from motion applications to CNC/robot control

CODESYS Safety

DIN 61508-certified safety software — appropriate solutions for all fields of application for SIL2 and SIL3 integrated in CODESYS

CODESYS ® is the leading manufacturer-independent IEC 61131-3 automation software for engineering control systems.

CODESYS Technology Day 2023

50 Shades of CODESYS

This was the headline of the presentation held by Bernhard Reiter, Product Manager at the CODESYS Group at CODESYS Technology Day 2023.

Curious about what’s behind it? Then make sure to watch the video. Without giving too much away: It is about the modularization of CODESYS.

PS: The next Tech Day video will focus on machine simulation with CODESYS – stay tuned!

All CODESYS Technology Day videos that have been published so far can be found here.

CODESYS

Специализированное программное решение, которое предназначено для программирования логических контроллеров от российской компании ОВЕН.

Бесплатная

CODESYS — это система разработки, которая позволяет выполнять программирование СПК — сенсорных программируемых контроллеров. В России и странах СНГ чаще всего применяется для работы с контроллерами и датчиками от компании ОВЕН, так как именно они чаще всего используются на производстве. ПО полностью отвечает требованиям МЭК и может работать со всеми популярными языками программирования (в том числе ООП). В распоряжение кодера предлагается удобная рабочая среда, напоминающая таковую во многих популярных IDE, например, RAD Studio.

Состав

Controller Development System (именно так звучит полное название CODESYS) состоит из системы исполнения и среды программирования. Первая отвечает за интеграцию с СПК, а также выполнение тестирования кода. Кстати, помимо работы с сенсорными программируемыми контроллерами, система исполнения может быть адаптирована к другим аппаратным платформам.

В здешних редакторах кода вы сможете создавать прикладные приложения, определяющие работу логических контроллеров. Да именно в редакторах, потому как таковой здесь не один. CODESYS предлагает среду для работы с ассемблер-подобными инструкциями, языком релейно-контактных схем и блоковых диаграмм, а также с паскаль-подобным структурированным текстом. Система включает в себя набор компиляторов, преобразующих написанные инструкции в машинный код. Помимо компиляторов присутствуют также встроенные отладчики, помогающие эмулировать поведение СПК и выявлять недочеты в созданных инструкциях. Отладка выполняется уже после подключения к совместимому устройству.

Совместимость

CODESYS поддерживает микропроцессоры с различной архитектурой: ARM, PowerPC, MIPS, Blackfin, Infineon и так далее. В плане программной совместимости данная система является довольно универсальной и работает на всех современных версиях Windows. Требования к «железу» ПК у программы минимальны.

Ключевые особенности

- позволяет программировать промышленные контроллеры;

- предлагает богатый набор компиляторов и инструментов отладки;

- умеет подключаться и работать с самыми разными моделями микропроцессоров;

- полностью соответствует требованиям МЭК;

- предлагает удобную рабочую среду;

- переведена на русский язык и доступна совершенно бесплатно.

При подготовке материала использовались источники:

https://www.codesys.com/the-system/why-codesys.html

https://www.codesys.com/

https://softrare.space/ru/windows/codesys/

Онлайн Радио 24

Онлайн Радио 24